Thinking Outside the box - Old school craftsmen and New Technology Still has it's place

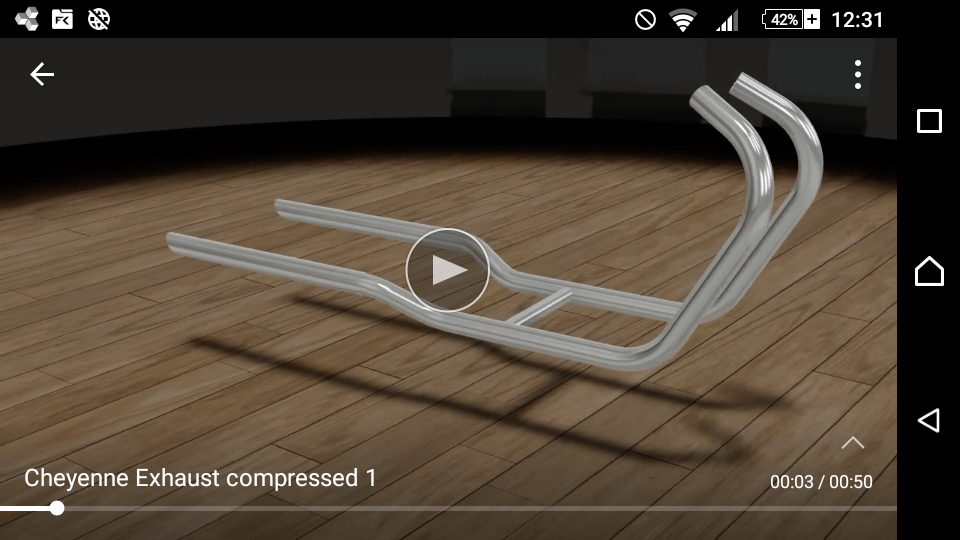

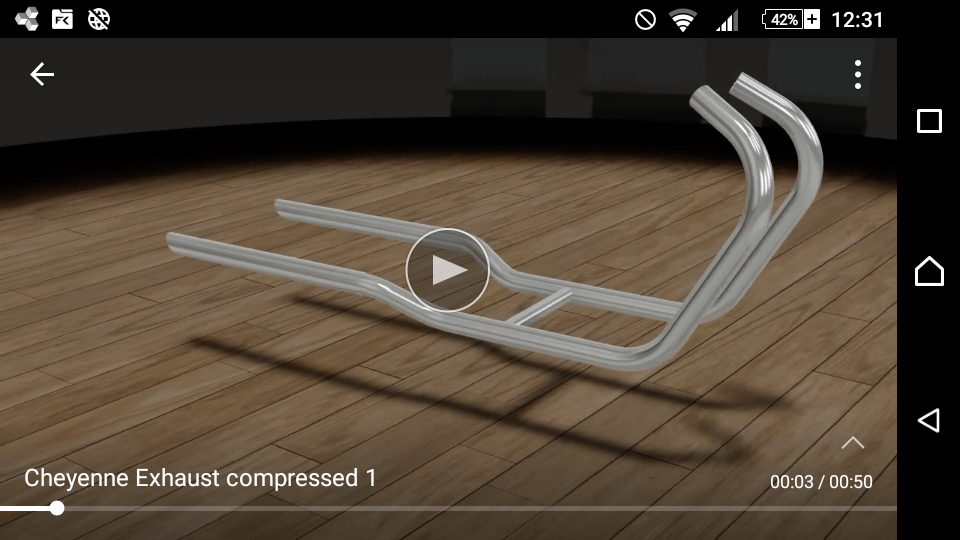

Having got Cheyenne's ideas of what she wanted in an exhaust style scribbled down on a piece of paper, I generated a design based on the known angles of available stainless 1" 3/8 bends.

Not precisely to size and accurate to the engine dimensions, but accurate enough to produce a 3D model and create a video roll around of the proposed design for approval.

Now is where it gets interesting...

There are people who could take this, roll it out on a CNC bender, then on to a fabricator for welding - but it's very pricey for a one off design...or

You could find an exhaust fabricator who works by hand and eye, for the price he's competitive at, take him the design concept and a couple of drawings for reference, the engine in frame knowing exactly the resting frame angle you're aiming for, and sit it on his fabrication bench on jacks to set it up correctly for alignment.

Then, he hand fabricates the look you're after, to the key point of the actual bike, in 3 days, for £420.

A mass produced custom exhaust costs more! Old tech meets new tech for a bit of a chinwag...

Not precisely to size and accurate to the engine dimensions, but accurate enough to produce a 3D model and create a video roll around of the proposed design for approval.

Now is where it gets interesting...

There are people who could take this, roll it out on a CNC bender, then on to a fabricator for welding - but it's very pricey for a one off design...or

You could find an exhaust fabricator who works by hand and eye, for the price he's competitive at, take him the design concept and a couple of drawings for reference, the engine in frame knowing exactly the resting frame angle you're aiming for, and sit it on his fabrication bench on jacks to set it up correctly for alignment.

Then, he hand fabricates the look you're after, to the key point of the actual bike, in 3 days, for £420.

A mass produced custom exhaust costs more! Old tech meets new tech for a bit of a chinwag...